Step 1: Create the Vivado Hardware Design and Generate XSA¶

In this step, we will create the hardware design for the ZCU104 Vitis acceleation platform. We will start from a ZCU104 preset design, add platform required peripherals and configure them. After everything is set, we will export the hardware design to XSA.

Create Base Vivado Project from Preset¶

Launch Vivado

Run the following commands in Linux console.

source <Vitis_Install_Directory>/settings64.sh vivado &

Create a Vivado project named zcu104_custom_platform.

Select File->Project->New, Click Next.

In Project Name dialog set Project name to zcu104_custom_platform. Click Next.

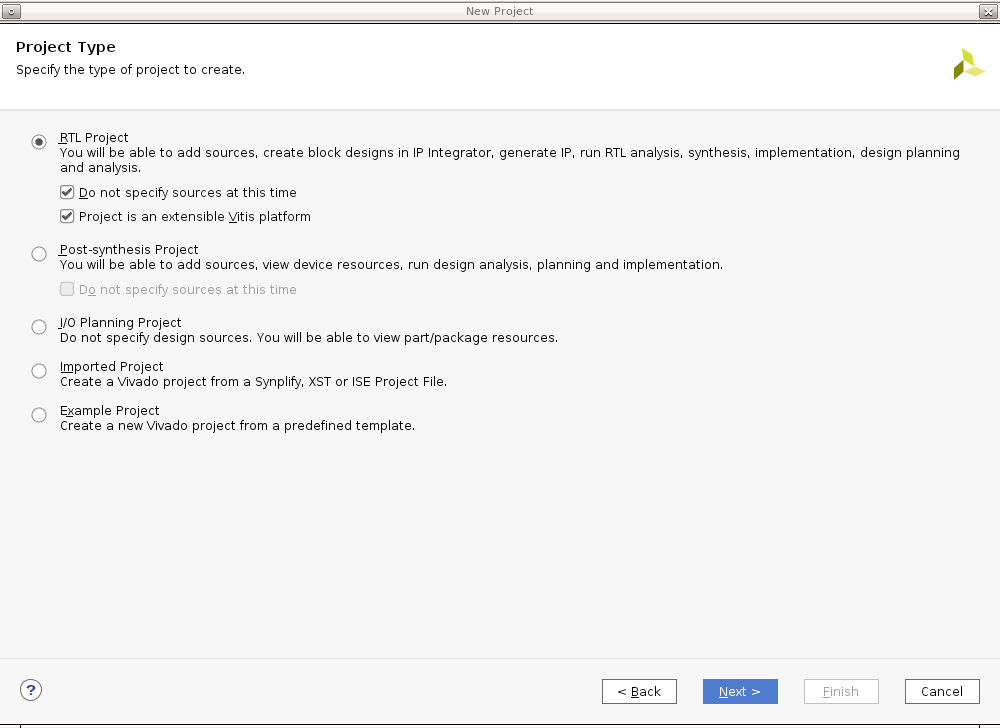

Enable Project is an extensible Vitis platform. Click Next.

Select Boards tab and then select Zynq UltraScale+ ZCU104 Evaluation Board. Click Next.

Review project summary and click Finish

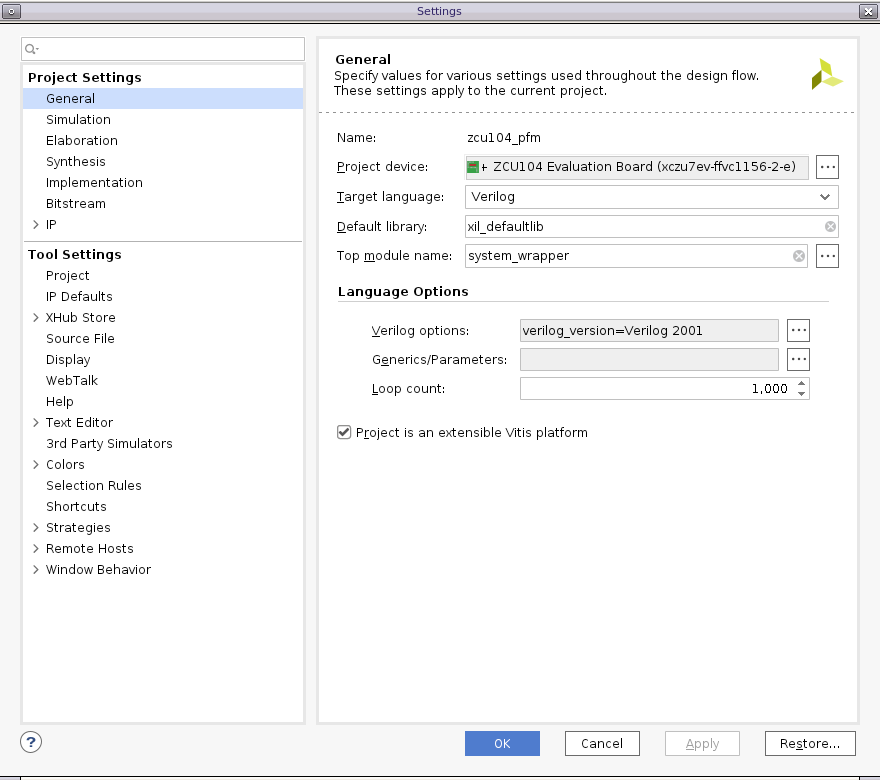

Note: If you need to change an existing Vivado project to an extensible platform project, you can go to Settings in Flow Navigator in an opened Vivado design, go to General and enable project is an extensible Vitis platform

Create a block design.

In Project Manager, under IP INTEGRATOR, select Create Block Design.

(Optional) Change the design name to system.

Click OK.

Add MPSoC IP and run block automation to configure it.

Right click Diagram view and select Add IP.

Search for

zynqand then double-click the Zynq UltraScale+ MPSoC from the IP search results.Click the Run Block Automation link to apply the board presets. In the Run Block Automation dialog, ensure the following is check marked:

All Automation

Zynq_ultra_ps_e_0

Apply Board Presets

Click OK. You should get MPSoC block configured like below:

What Just Happended?

At this stage, the Vivado block automation has added a Zynq UltraScale+ MPSoC block and applied all board presets for the ZCU104. The presets includes MPSoC PS block configurations and pin assignments.

What to do for custom boards?

For a custom board, please double click MPSoC block and setup parameters according to the board hardware. Next we’ll add the IP blocks and metadata to create a base hardware design that supports acceleration kernels.

Customize System Design for Clock and Reset¶

V++ linker can automatically link the clock signals between kernel and platform. The available clock signals in the platform are exported by PFM.CLK property.

For simple designs, interrupt signals can be sourced by processor’s pl_clk. The limitation is that the processor has maximum 4 pl_clks and their phase is not aligned.

To provide more interrupt signals, or to provide phase aligned clocks, we can use Clocking Wizard.

We will add the Clocking Wizard to the block diagram and enable clock signals for the platform. Here are the detailed steps.

Add the clocking wizard block to generate three clocks:

Right click Diagram view and select Add IP.

Search for and add a Clocking Wizard from the IP Search dialog.

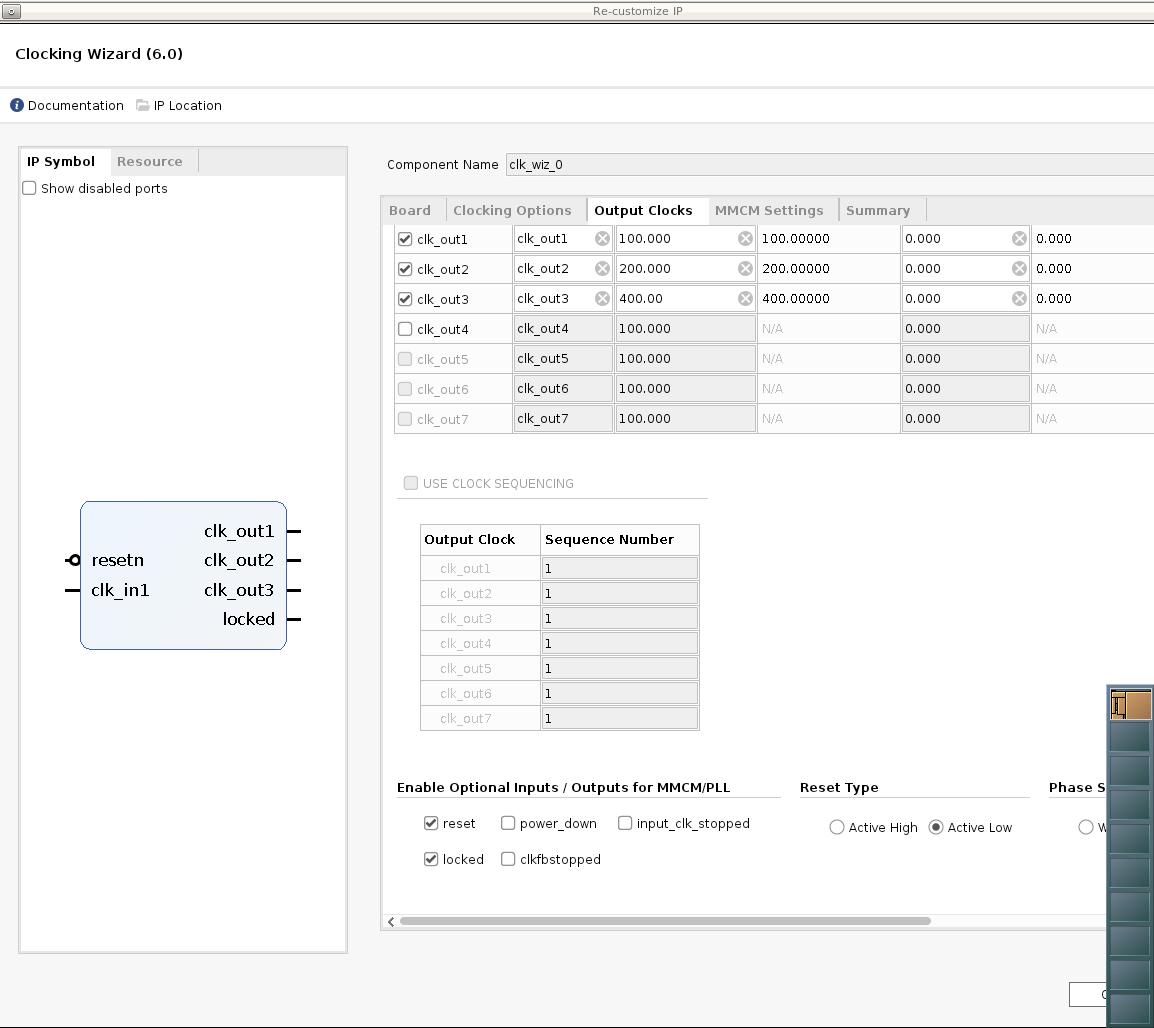

Double-click the clk_wiz_0 IP block to open the Re-Customize IP dialog box.

Click the Output Clocks tab.

Enable clk_out1 through clk_out3 in the Output Clock column. Set the Requested Output Freq as follows:

clk_out1 to 100 MHz.

clk_out2 to 200 MHz.

clk_out3 to 400 MHz.

At the bottom of the dialog box set the Reset Type to Active Low.

Click OK to close the dialog.

Note: So now we have set up the clock system for our design. This clock wizard uses the pl_clk as input clock and generates clocks needed for the whole logic design. In this simple design, we would use 100MHz clock as the axi_lite control bus clock. 200MHz and 400MHz clocks are reserved for DPU AXI interface clock and DPU core clock during design linking phase. You are free to modify the clock quantities and frequency to fit your target design. We’ll setup the clock export in future steps. Before that, we need to create reset signals for each clock because they are needed in clock export setup.

Add three Processor System Reset blocks corresponging to the three clocks:

Right click Diagram view and select Add IP.

Search for and add a Processor System Reset from the IP Search dialog

Rename the reset block to proc_sys_reset_1 so that it’s easy to understand the relationship between reset modules and the clock signals.

Select the proc_sys_reset_1 block, type Ctrl-C and Ctrl-V to replicate two modules. They are named as proc_sys_reset_2 and proc_sys_reset_3 by default.

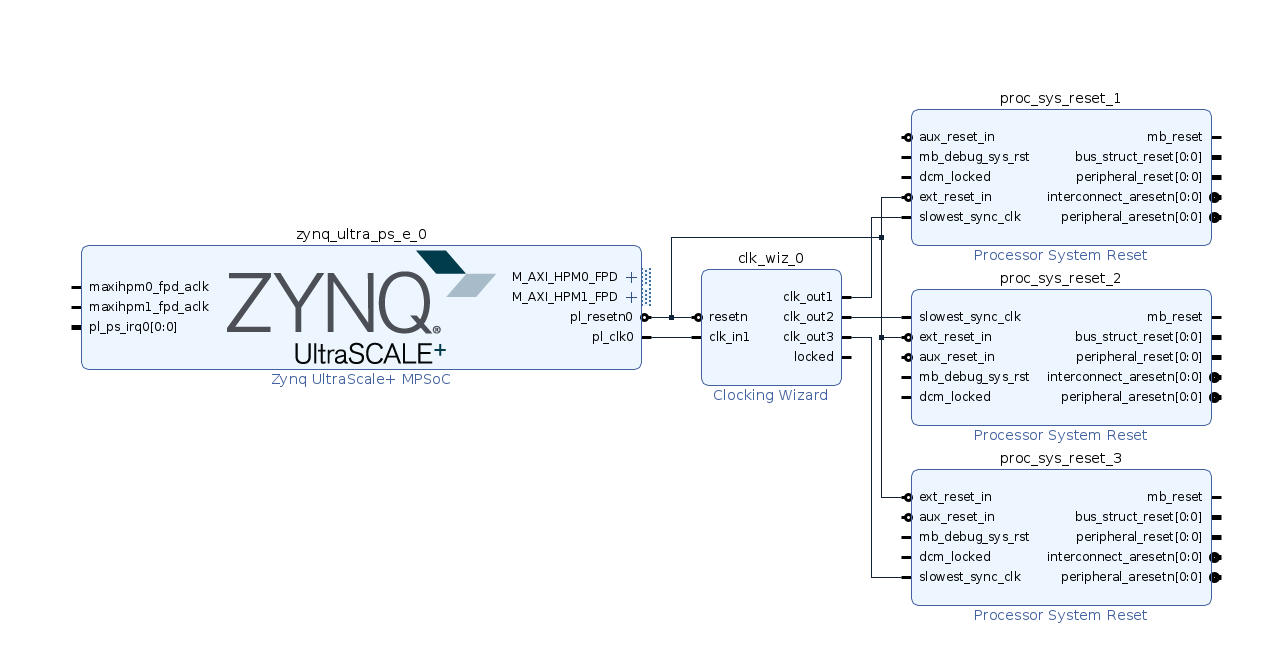

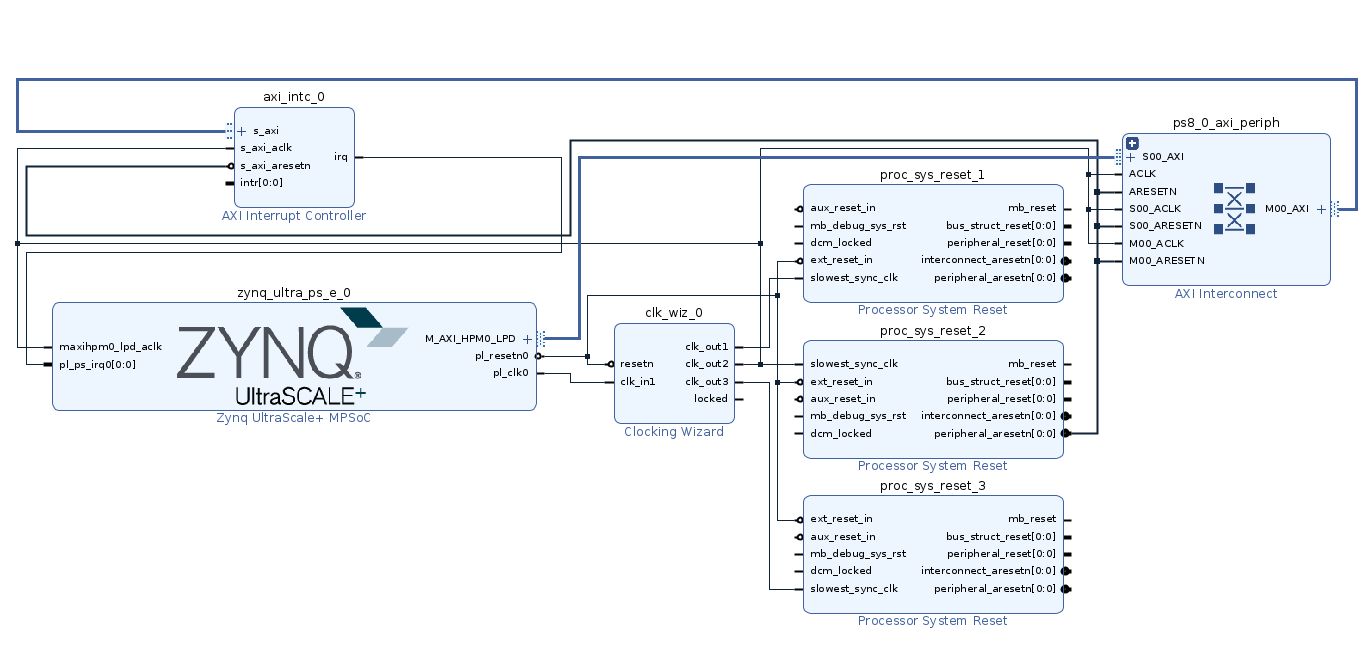

Connect Clocks and Resets:

Click Run Connection Automation, which will open a dialog that will help connect the proc_sys_reset blocks to the clocking wizard clock outputs.

Enable All Automation on the left side of the Run Connection Automation dialog box.

Select clk_in1 on clk_wiz_0, and set the Clock Source to /zynq_ultra_ps_e_0/pl_clk0.

For each proc_sys_reset instance, select the slowest_sync_clk, and set the Clock Source as follows:

proc_sys_reset_1 with /clk_wiz_0/clk_out1

proc_sys_reset_2 with /clk_wiz_0/clk_out2

proc_sys_reset_3 with /clk_wiz_0/clk_out3

On each proc_sys_reset instance, select the ext_reset_in, set Board Part Interface to Custom and set the Select Manual Source to /zynq_ultra_ps_e_0/pl_resetn0.

Make sure all checkboxes are enabled, and click OK to close the dialog and create the connections.

Connect all the dcm_locked signals on each proc_sys_reset instance to the locked signal on clk_wiz_0.

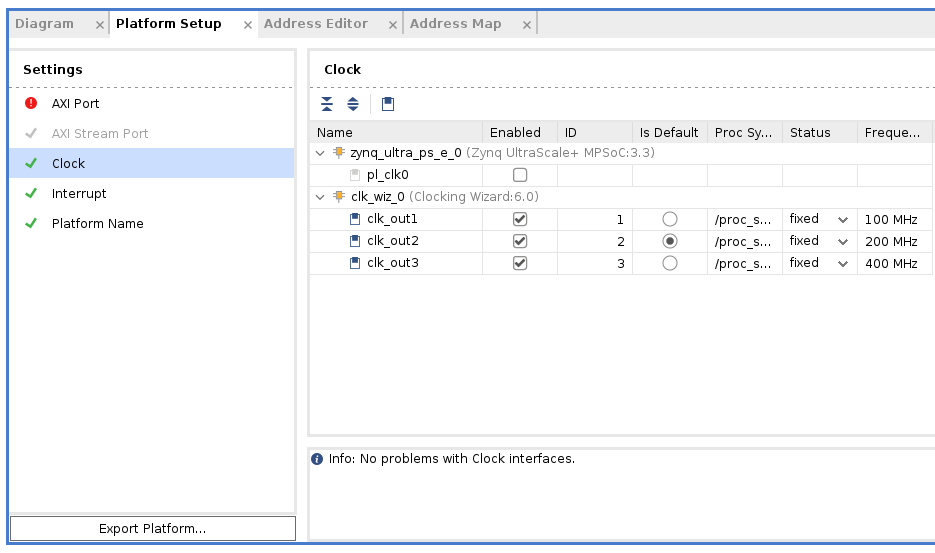

Enable clocks for the platform

Go to Platform Setup tab.

If it’s not opened yet, use menu Window -> Platform Setup to open it.

Click Clock tab

Enable all clocks under clk_wiz_0: clk_out1, clk_out2, clk_out3

Change their ID to 0, 1 and 2

Set a default clock: click Is Default for clk_out2

After everything is setup, it should report Info: No problem with Clock interface.

Note:

There should be one and only one default clock in the platform. During v++ linker will use the default clock to connect the IP blocks if there are no user assignments for link configuration.

Add Interrupt Support¶

V++ linker can automatically link the interrupt signals between kernel and platform. The available interrupt signals in the platform are exported by PFM.IRQ property.

For simple designs, interrupt signals can be sourced by processor’s pl_ps_irq. The limitation is that it can only provide maximum 16 interrupt signals. To provide more interrupt signals, We can use AXI Interrupt Controller. We’ll enable AXI HPM0 LPD to control the AXI Interrupt Controller, add the AXI Interrupt Controller and enable interrupt signals for PFM.IRQ. Here are the detailed steps.

Enable AXI HPM0 LPD to control the AXI Interrupt Controller

In the block diagram, double-click the Zynq UltraScale+ MPSoC block.

Select PS-PL Configuration > PS-PL interfaces > Master interface.

Enable the AXI HPM0 LPD option.

Expand the arrow before AXI HPM0 LPD. Check the AXI HPM0 LPD Data width settings and keep it as default 32.

Disable AXI HPM0 FPD and AXI HPM1 FPD

Click OK to finish the configuration.

Note:

We use AXI HPM0 LPD mainly for controlling purpose. It would read and write 32 bit control registers. If the interface is more than 32, AXI Interconnect or SmartConnect will do AXI bus width conversion using PL logic. It would cost logic resource and introduce unnecessary latency.

We reserve AXI HPM0 FPD and AXI HPM1 FPD for kernel usage. Disabling them from the block diagram can prevent auto connection to use it by accident. We can export the unused AXI interfaces in Platform Setup, no matter it’s visible in the block diagram or not.

Add the AXI Interrupt Controller and configure it

Right click Diagram view and select Add IP, search and add AXI Interrupt Controller IP. It’s instantiated as axi_intc_0.

Double click the AXI Interrupt Controller block, change Interrupt Output Connection to Single so that it can be connected to PS IRQ interface.

Click OK.

Connect AXI Interfaces of axi_intc_0 to AXI HPM0 LPD of PS

Click Run Connection Automation

Review the settings (axi_intc_0 is enabled, s_axi is to be connect to /zynq_ultra_ps_e_0/M_AXI_HPM0_LPD)

Set Clock Source for Slave Interface and Clock Source for Master Interface to /clk_wiz_0/clk_out2(200 MHz)

Click OK

Note:

We wish interrupt controller and most kernel IRQ signals are synchronous to one clock. It’s best for stability. But don’t worry about the asynchronous IRQ if kernels are running at different clocks. The interrupt controller can handle asynchronous IRQ with level interrupt signals as well.

Connect irq of the Interrupt Controller

Connect axi_intc_0.irq to zynq_ultra_ps_e_0.pl_ps_irq[0:0]

Note:

If you have more than one irq signals to connect to pl_ps_irq of PS, use a concat IP to concatenate them to a bus and then connect the bus to pl_ps_irq.

Enable interrupt signals for the platform.

Go to Platform Setup tab

Go to Interrupt tab

Enable intr under axi_intc_0

Tcl console shows the corresponding tcl command for this setup:

set_property PFM.IRQ {intr { id 0 range 32 }} [get_bd_cells /axi_intc_0]

The IPI design connection would like below till now:

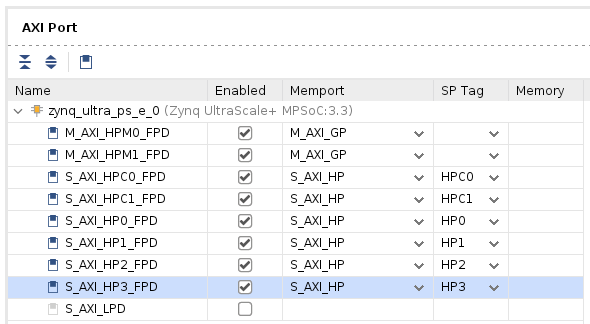

Enable AXI Interfaces for the Platform¶

Enable AXI Master interfaces from PS

Go to Platform Setup tab

Go to AXI Port tab in Platform Setup

Under zynq_ultra_ps_e_0, enable M_AXI_HPM0_FPD and M_AXI_HPM1_FPD. Keep the Memport and sptag default to M_AXI_GP and empty.

Note:

M_AXI_GP means general purpose AXI Master interface

sptag is only applicable to AXI slave interfaces.

v++ linker will instantiate AXI Interconnect automatically to connect between PS AXI Master interfaces and slave interfaces of acceleration kernels. One AXI Master interface will connet up to 16 kernels.

Enable AXI Master interfaces from AXI Interconnect

Under ps8_0_axi_periph, click M01_AXI, press Shift and click M07_AXI to multi-select master interfaces from M01_AXI to M07_AXI.

Right click the selection and click on Enable.

Keep the Memport and sptag default to M_AXI_GP and empty.

Note:

v++ will not cascade another level of AXI Interconnect if the AXI master interface is exported from AXI Interconnect IP.

AXI Master interfaces from PS and AXI Interconnect are functionally equvalent to the platform.

In general, platform designer should export as many as AXI interfaces to the platform. Application developer should decide which interface to use.

Enable AXI Slave interfaces from PS to allow kernels access DDR memory

Under zynq_ultra_ps_e_0, multi-select all AXI slave interfaces: press Ctrl and click S_AXI_HPC0_FPD, S_AXI_HPC1_FPD, S_AXI_HP0_FPD, S_AXI_HP1_FPD, S_AXI_HP2_FPD, S_AXI_HP3_FPD.

Right click the selections and select enable.

Change Memport of S_AXI_HPC0_FPD and S_AXI_HPC1_FPD to S_AXI_HP because we won’t use any coherent features for these interfaces.

Type in simple sptag names for these interfaces so that they can be selected by v++ configuration during linking phase. HPC0, HPC1, HP0, HP1, HP2, HP3.

Emulation Setup (Optional)¶

This step is only needed when creating an emulation-capable platform.

When a component comes with multiple types of simulation models, selecting SystemC TLM (Transaction-level Modeling) model would run much faster than RTL model. For Processing System component, it’s mandatory to use TLM for Hardware Emulation.

Change PS simulation model to tlm

Select the PS instance zynq_ultra_ps_e_0 in the block diagram

check the Block Properties window.

In Properties tab, it shows

ALLOWED_SIM_MODELS=tlm,rtl. It means this component supports two types of simulation models.Scroll down to

SELECTED_SIM_MODELproperty. Change it from rtl to tlm to select to use TLM model.Notice the equvalent Tcl command shown in tcl console is:

set_property SELECTED_SIM_MODEL tlm [get_bd_cells /zynq_ultra_ps_e_0]

Export Hardware XSA¶

Validate the block design

Click the Validate Design button in the block design Diagram window

Note: During validation, Vivado reports a critical warning that /axi_intc_0/intr is not connected. This warning can be safely ignored because v++ linker will link kernel interrupt signals to this floating intr signal.

CRITICAL WARNING: [BD 41-759] The input pins (listed below) are either not connected or do not have a source port, and they don't have a tie-off specified. These pins are tied-off to all 0's to avoid error in Implementation flow. Please check your design and connect them as needed: /axi_intc_0/intr

Create a top module wrapper for the block design

In Source tab, right click system.bd in Design Sources group

Select Create HDL Wrapper…

Select Let Vivado manage wrapper and auto-update.

Click OK to generate wrapper for block design.

Generate pre-synth design

Select Generate Block Design from Flow Navigator

Select Synthesis Options to Global. It will skip IP synthesis during generation.

Click Generate. .

Generate Bitstream

This step is only required for KV260 PetaLinux BSP, which we will build in next step. In most cases a flat (non-DFX) Vitis platform doesn’t need to generate bitstream before exporting the platform. It’s required here because the PetaLinux package

fpga-manager-utilrequires a bit file in the XSA file.Click Generate Bitstream in the navigation window.

Select a proper number of jobs for Launch runs on local host

Click OK to start building.

Export the platform

Click menu File -> Export -> Export Platform to launch the Export Hardware Platform wizard. This wizard can also be launched by Export Platform button in Flow Navigator or Platform Setup window.

Click Next in the first information page.

Select Platform Type: Hardware and Hardware Emulation, click Next. If you skipped the emulation setup previously, select Hardware here.

Select Platform State: Pre-synthesis, enable Include bitstream, click Next

Input Platform Properties and click Next. For example,

Name: zcu104_custom_platform

Vendor: xilinx

Board: zcu104

Version: 0.0

Description: This platform provides high PS DDR bandwidth and three clocks: 100MHz, 200MHz and 400MHz.

Fill in XSA file name: zcu104_custom_platform and keep the export directory as default.

Click Finish.

zcu104_custom_platform.xsa will be generated. The export path is reported in the Tcl console.

Alternatively, the above export can be done in Tcl scripts

# Setting platform properties set_property platform.default_output_type "sd_card" [current_project] set_property platform.design_intent.embedded "true" [current_project] set_property platform.design_intent.server_managed "false" [current_project] set_property platform.design_intent.external_host "false" [current_project] set_property platform.design_intent.datacenter "false" [current_project] # Write pre-synthesis expandable XSA write_hw_platform -force -file ./zcu104_custom_platform.xsa

Fast Track¶

Scripts are provided to re-create projects and generate outputs. To use these scripts, please run the following steps.

Run build

# cd to the step directory, e.g. cd step1_vivado make

To clean the generated files, please run

make clean

Next Step¶

Now we finish the Hardware platform creation flow, then we should go to the Step2: Software platform creation

Copyright© 2021 Xilinx