Kria™ KV260 Vision AI Starter Kit Defect Detection Tutorial |

Design Overview |

Design Overview¶

Introduction¶

Mango, known as the king of fruits, is an essential product that graces many kitchens. This juicy delicacy is processed into many forms such as pulp, drinks, jams, pickles, and many more tasty products. The Statistia website estimates that about 52 million metric tons of mangoes are produced each year globally, and production rises each year. A large percentage of mangoes are exported, bringing in a considerable influx of foreign exchange.

Given the importance of the mango in both household and export contexts, it is vital that each mango be without a single blemish of any kind. Due to the large volumes of mangoes produced, it is practically impossible to manually examine each mango for defects. An automated way of marking defects is the need of the hour.

The Defect Detection application uses AMD Vitis™ Vision libraries to examine each mango and mark its defects. This helps farmers sell the best mangoes to bring in enhanced revenue and results in a win-win situation for both the farmers and the consumers.

Get on with the times! Use the AMD automated Defect Detection application to select the best for those demanding, discerning customers.

Defect Detection Application¶

This is a getting started document for Defect Detection accelerated application developed on an AMD SOM embedded platform. This document covers various components such as hardware, software, design, test environment, and more.

The SOM platform is a computer vision application platform that is capable of sourcing input data from a file, accelerating the core application algorithm in hardware, and then sending the output to DP/HDMI-TX/File.

The following table lists the specific hardware (SOM + Carrier card) and the associated peripherals used in the Defect Detection accelerated application.

| HW Component | Definition |

|---|---|

| SOM-K26 | K26 SOM with Zynq™ UltraScale+™ MPSoC |

| Carrier Card (CC)-KV260 | The board that the SOM is plugged into is called the Carrier Card |

| ____ |

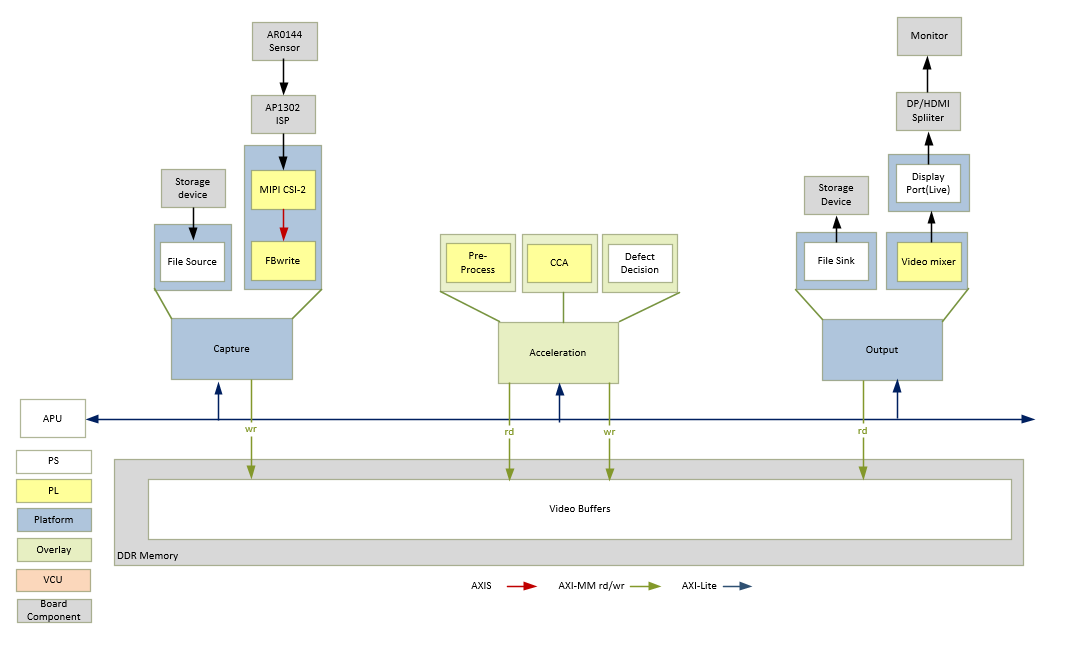

The Defect Detection reference design has the following pipelines:

Capture Pipeline: Capture images of mangoes from the file.

Acceleration Pipeline:

Pre-Process Pipeline: Pre-Process the received images as required for the processing function.

CCA Pipeline: The implemented Connected Component Analysis (CCA) is a custom solution to find the defective pixels in the problem object. This algorithm considers few assumptions that the background must be easily separable from the foreground object.

Defect Decision Pipeline: The output of the CCA plugin is fed into the Defect Decision block that determines the defect density and decides the quality of the mango.

Display Pipelines: Display detection results and images of the mango at various stages.

The following figure shows the various pipelines supported by the design.

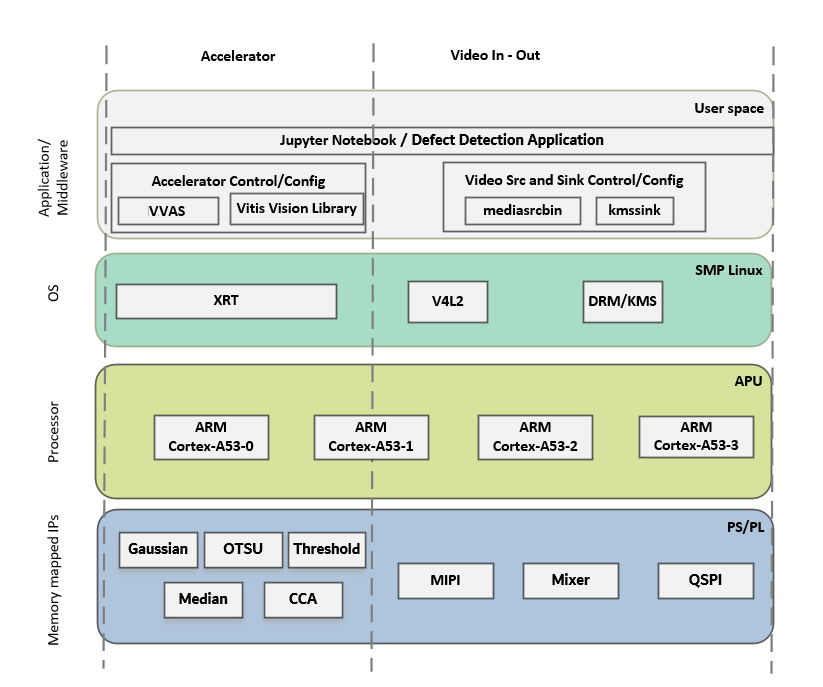

The application processing unit (APU) in the processing system (PS) consists of four Arm®Cortex®-A53 cores and is configured to run in symmetric multi-processing (SMP) Linux mode in the design. The application running on Linux is responsible for configuring and controlling the video pipeline and accelerators using Jupyter notebooks or the application. The following figure shows the software state after the boot process has completed and the individual applications have been started on the APU. Details are described in the Software Architecture document.

The APU application controls the following video data paths implemented in a combination of the PS and PL.

Capture pipeline capturing video frames into DDR memory from:

A file on a storage device such as an SD card.

An image sensor connected via MIPI CSI-2 RX through the PL.

An output pipeline reads video frames from memory and sends the frames to a sink.

The sink is a display/file storage.

The DP controller subsystem in the PS is coupled to the STDP4320 De-multiplexer on the carrier card. STDP4320 consists of dual mode output ports configured as the DP/HDMI.

Key Features of the Defect Detection Application¶

The Defect Detection application detects defects in a mango. The application supports file-based use cases.

File-based usage accepts the input GRAY8 file (Y8 format) and returns three outputs in GRAY8 format.

For the live use case, connect the AR0144 sensor to capture 1280x800@60fps GRAY8 data. The application processes this data and sends the outputs to the display.

NOTE: The Y8 file is playable using a YUV player. Because the Y8 file is a raw file, you might need to drag and drop the file to the player of your choice, set the proper size (width=1280, height=800), and use Y color format.

The output can come from any of the following stages of processing:

Stage 1 of the output belongs to input GRAY8 data

Stage 2 of the output belongs to pre-processed pipeline

Stage 3 of the output belongs to the final stage defect detection pipeline

Various Components Used in this Application¶

Tools

AMD Tools

Vitis: 2022.1

Vivado™ tool: 2022.1

Hardware

Hardware Components

Target platforms and extensions

Kria KV260 Vision AI Starter Kit including:

On Semi AP1302 Image Signal Processor on the carrier card

DP splitter on the carrier card

Hardware interfaces and IP

Video Inputs

File

MIPI CSI-2 RX

Video Outputs

File

DisplayPort/HDMI

Auxiliary Peripherals

QSPI

SD

I2C

UART

Ethernet

General-purpose I/O (GPIO)

Software

Software Components

Video Processing: Vitis Vision library accelerator functions

Operating System (OS)

APU: SMP Linux

Linux Kernel Subsystems

Video Source: Video4 Linux (V4L2)

Display: Direct Rendering Manager (DRM)/Kernel Mode Setting (KMS)

Linux User Space Frameworks

Jupyter Notebook

GStreamer/VVAS

Xilinx runtime (XRT)